Regional development scenarios for urban water management

CABUWAZI climate exhibition

Research for decentralised water reuse

In our latest research project, DeWaResT [1], we are focusing entirely on Nature Based Solutions (NBS) to make used water from households reusable. It has long been a nuisance that high-quality drinking water is first used for flushing toilets and then has to be pumped to the sewage treatment plant, sometimes via long pipes. Afterwards, it is no longer available to the local water balance and leads, more or less well purified, to an unavoidable and, with decreasing runoff, increasing chemical pollution of the water bodies. It is already clear that rising temperatures are causing a sharp increase in water consumption in the landscape. At the same time, there is less precipitation in some regions of Brandenburg. As a result, groundwater levels are sinking and lakes and watercourses are drying out.

According to the European Directive 91/271/EEC and the Brandenburg Municipal Wastewater Ordinance (§7 BbgKAbwV), water abstraction from natural sources should therefore be reduced and treated wastewater reused wherever possible. However, high demands are placed on the reuse of treated wastewater in agriculture to protect the environment and products. It is estimated that the wastewater collected in decentralised collection pits in Brandenburg could cover up to 20% of the irrigation needs in agriculture if it were appropriately treated in a decentralised manner. In the future, the European Water Reuse Regulation (EU-WVVO) will regulate the requirements for purification and monitoring.

The contribution of our research project is to enable such decentralised water cycles. For this purpose, constructed wetlands are optimised in terms of process technology and combined with further purification stages as required. Such vegetated soil filters are particularly suitable for decentralised application due to their simple and robust operation. Integrated stages are designed to further remove germs and trace substances.

The innovative soil filter is compact and requires a very small surface area. Two pilot plants in Brandenburg are used for optimisation and further development. The Pehlitzwerder plant serves to prove its applicability at a remote natural camping site with very high nature conservation requirements in the middle of the Schorfheide-Chorin biosphere reserve. The second plant treats regular household wastewater. After completion of the investigations in 2023 and evaluation of the results, this new type of constructed wetland should be available for future decentralised applications. This is intended to close the gap in agricultural (economic) water reuse. This research is funded by the Federal Ministry of Education and Research (BMBF) in the funding measure “KMU-innovativ”, technology field “Resource Efficiency and Climate Protection”, application area “Sustainable Water Management”. The project partner is KWB Kompetenzzentrum Wasser gGmbH, Berlin.

Further information: Heribert Rustige

[1] Decentralised wastewater treatment and water reuse for regions with seasonal drought stress

Research for decentralised water reuse

River bath Berlin: Research results presented

CABUWAZI climate exhibition

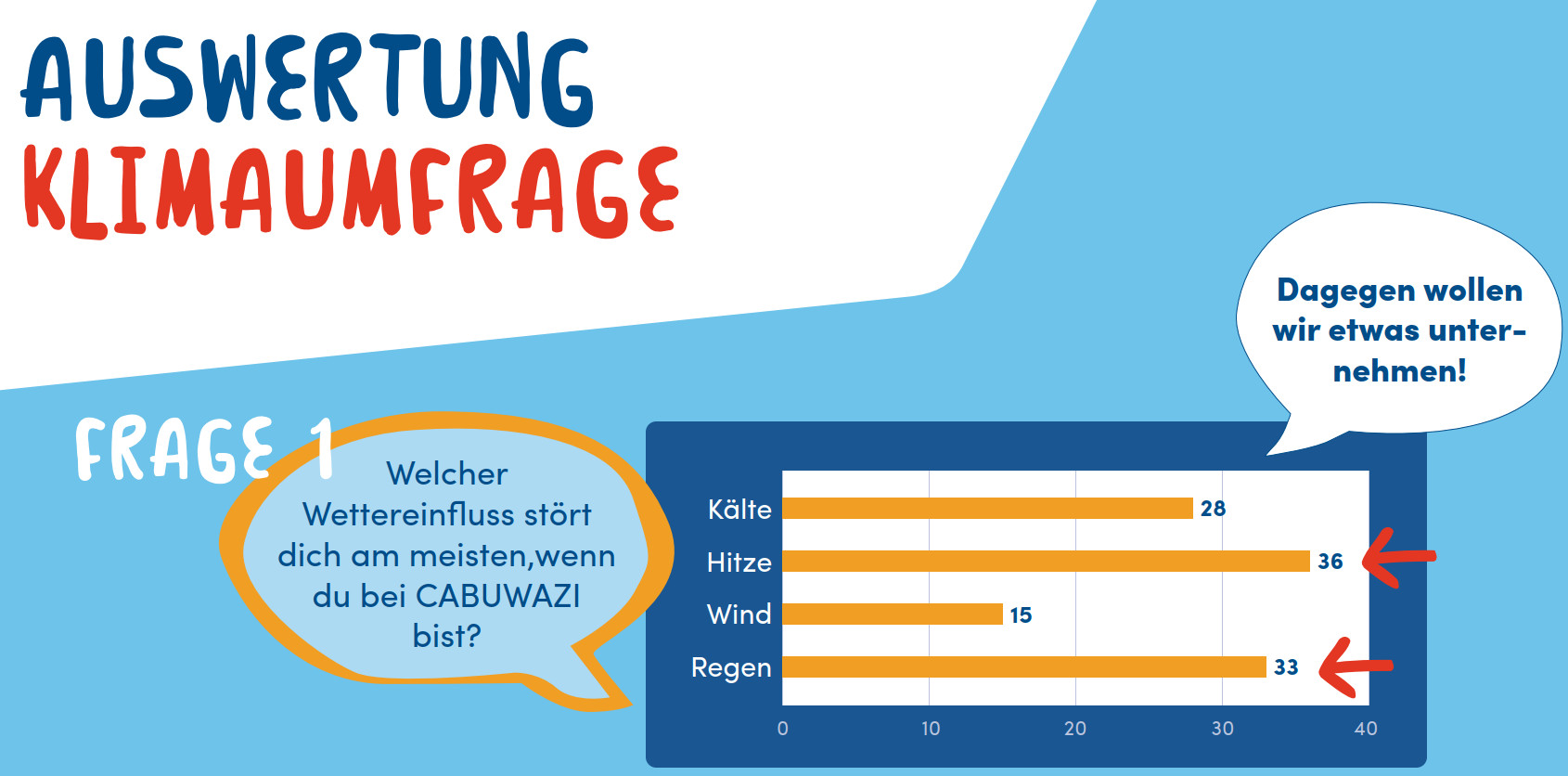

At the Berlin children’s and youth circus CABUWAZI, climate change and its consequences are omnipresent. This is particularly noticeable at the six locations in the city. The large circus tents heat up strongly in summer, as do the circus wagons and containers at the respective locations. For this reason, AKUT was commissioned to conduct a feasibility study for measures to adapt to the consequences of climate change as early as 2021. The study was funded by the BMU as part of the funding program for “Climate adaptation in social institutions” (duration 2020 – 2023). The results of the work, in which the children and young people as well as the circus trainers working on site were involved, were summarized in an exhibition that is now traveling from site to site.

“Climate change” has become a constantly recurring term. Not least through the student demonstrations of Fridays for Future, which have succeeded in putting the findings of science and the associated need for action on the political agenda. The children and young people experience first-hand what the consequences of climate change feel like during summer heat waves in the city.

However, what exactly climate change is and how it works is not clear to all children and young people as well as adults. For this reason, the desire arose to provide information about the topic within the framework of a traveling exhibition. Divided into three thematic areas, nine posters explain climate change and its consequences on both a global and a local scale. The three posters of the first block explain the origin of climate change and how it affects the people in the world and in Berlin. This will be followed by an analysis of the most exciting results of the CABUWAZI climate survey. This was conducted in February 2022 among regular visitors to the circus offerings and filled out by over 100 participants. Wishes and ideas that emerged were included in the catalog of measures to reduce the climate impact at CABUWAZI. These are presented and explained in outline form in the last part of the poster exhibition.

Download: Poster exhibition (german)

CABUWAZI climate exhibition

Public swimming pool with biofilter in Neustadt (Dosse)

River bath Berlin: Research results presented

The staff of AKUT environmental engineers spent four years in Berlin on the research barge “Hans Wilhelm” studying the treatment of water from the River Spree. Now Heribert Rustige presented the results at the press conference of the Flussbad Berlin e.V. association. The association had commissioned AKUT in 2017 to test biological filters for improving bathing water quality in the Spree Canal. For this purpose, the research barge was placed at the location of the planned water filter at the height of the former Staatsrat building in Berlin’s city centre. Here it was closely observed by numerous tourists and Berliners and the AKUT team had to answer many questions about bathing in the Spree. This report summarises the most important answers.

With the help of the water analyses, it was found that the water quality in the Spree Canal had already improved continuously during the investigation period. This is especially true for the decreasing suspended particle contents, which caused an increase in the visibility depth in the Spree Canal. This trend was confirmed in comparison with long-term data series of the Spree and suggests already successful water protection measures in the city. Against this background and due to the tested filter variants, the cleaning concept can probably be realised with a filter size reduced by 2/3.

Based on the measured, briefly increased microbial loads on a few days a year, it was possible to clearly distinguish the polluted phases due to combined sewer discharges from the unpolluted phases. This enables a targeted step-by-step treatment in a resource-saving concept. This envisages a biofilter, which is normally sufficient to guarantee good bathing water quality according to the EU Bathing Water Directive. As soon as the automatic level measurements in the sewer network of Berliner Wasserbetriebe signal the overflow of combined water, additionally switched-on UV lamps would ensure safe hygienisation. Alternatively, filter operation could then be automatically interrupted for one to two days. This would also safely protect the following watercourse section from microbial overloading.

The research results allow the planning and dimensioning of biofilters for river water treatment. Five different filter materials with or without vegetation were examined. The elimination rates of E. coli and other indicator organisms were determined on the basis of loading tests. The best combination was found to be the use of porous expanded clay with reed planting. The results are an important addition to the know-how available so far, also for outdoor pools with biological water treatment. Experiences and technical innovations made here can be transferred to other water bodies and locations or enable targeted further investigations. We would like to thank the sponsors Xylem (UV -reactor), Rehau (drainage system) and ARGEX Belgium (expanded clay material) for their technical support.

Contact: Heribert Rustige